Product available in: Vic, Sa, Qld

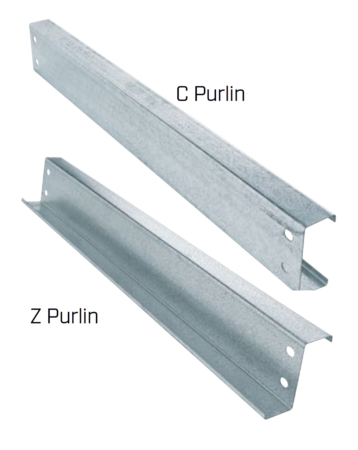

Apex Purlins and Girts are roll-formed from Hi-Tensile Galvanised steel. They are primarily used to provide lightweight, economical, efficient roofing and cladding support systems for framed structures. Apex Purlins and Girts are available in a range of different sizes and configurations.

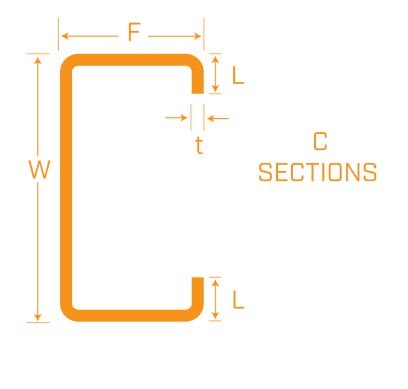

C-sections have equal flanges and may be used in single spans and unlapped continuous spans in multi-bay buildings. Their freestanding stable shape allows easy handling and storage and is easily adapted for use in small and medium sized buildings as structural framework.

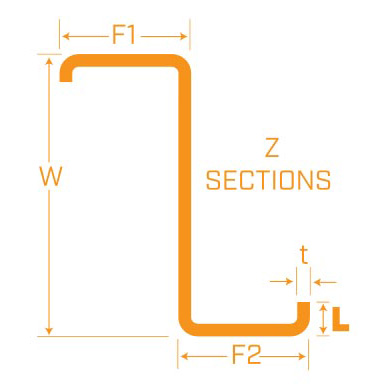

Z-sections feature one broad and one narrow flange allowing the two sections to fit together snugly, making them suitable for lapping. Z sections of the same depth and different thickness’ can be lapped in any combination. Purlins and Girts that are lapped form a structurally continuous line along the length of the building, a factor that contributes significantly to the reduction in building costs. Apex offers the added flexibility of downturn lips and adjustable top flanges for all sizes. Downturn lip purlins are ideal in applications where environmental conditions or build up of substances like dust or grain are a consideration. For special or large projects, Apex is able to customise sections outside the standard range to suit your individual requirements.

Purlins Load Tables – Click Here

Ultra-Purlins Information – Click Here

|

|

||||||||||||

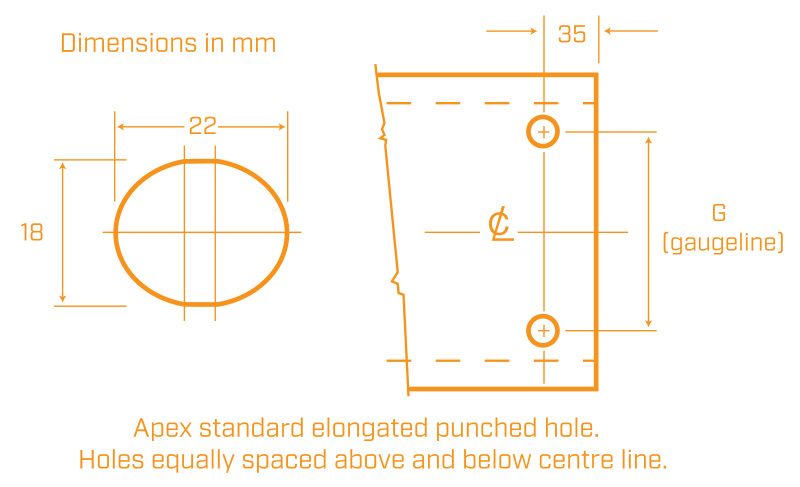

For special projects the size of the hole, |

HOLES – Apex Purlins and Girts are available custom punched to your requirements complying with the Australian institute of steel construction gauge lines as tabled below.

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||

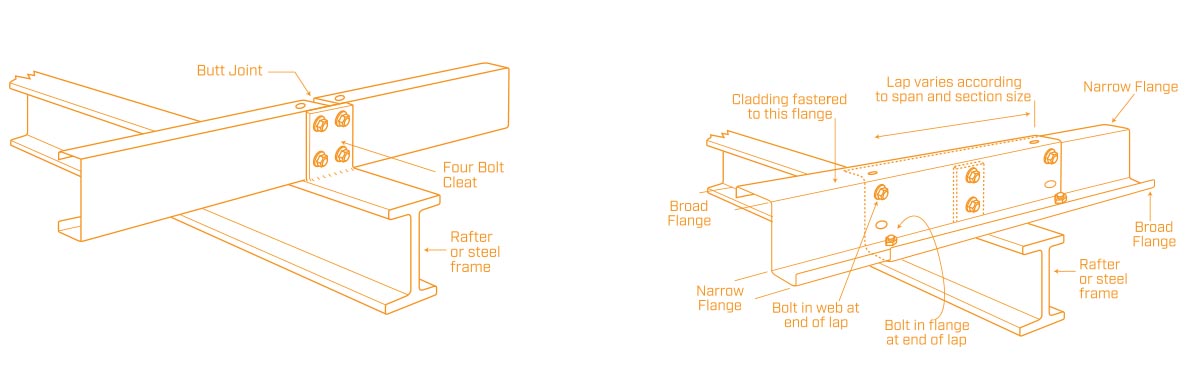

| Cleat Connection | Lapped Connection (Cleatless) | |

| The cleat connection is assembled by fastening two bolts through the web of the purlin to a cleats so that the load is supported via the web of the sections. The connections can be a single thickness to match the end connection section, or the internal support connection of a lapped connection. | A lapped connection is the fixing of purlins through the bottom and/or top flange of the purlin is used in certain variations of construction. The capacity tables are not to be used for lapped connections, for these types of connections there are more considerations (both strength and accessibility) and construction concerns that need to be considered. |