RECOMMENDED FIXING METHOD

When fastening into Steel Purlins, use 10 Gauge x 16mm Hex Head Screws, 4 per clip.

When fastening into timber battens, use 12 Gauge x 25mm Hex Head Type 17 screws, 4 per clip (softwood), and use 12 Gauge x 40mm Hex Head Type 17 screws, 4 per clip (hardwood). Allow 1.3 clips per square metre. This is based on 1200mm batten centres

MATERIALS

G550 base material (550Mpa minimum yield stress) with ZINCALUME® (AZ150) coating, in accordance with AS1397. COLORBOND® is available in a number of colours and thicknesses. Please inquire with our sales department for availability.

Note: in some areas/applications Apdeck 700 0.42BMT can be used at a 1 degree roof pitch. Please refer to attached document J970 for further information

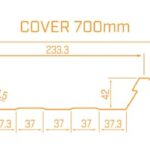

| BMT | TCT | MASS KG/M2 | COVER (MM) | ROOF INTERNAL | ROOF END | ROOF PITCH |

|---|

| 0.42 | 0.47 | 4.74 | 700 | 1800 | 1500 | 2 deg |

| .48 | 0.53 | 5.37 | 700 | 2400 | 1800 | 1 deg |

ADVERSE CONDITIONS

If the distance is within 1km of salt marine or industrial or corrosive environments, please contact our office for advice.

WARRANTIES

Our products are supported by Bluescope Steel Limited and a full warranty is available.

TESTING

Apdeck 700 has been fully tested by Vipac Engineers and Scientists Limited and in accordance with AS1170.2 and AS1562.1. Detailed test results are available upon request.

LENGTHS

Apdeck 700 is available in custom cut lengths to your requirements. Please check with our office as to what is the maximum length we can transport as restrictions apply.

HANDLING

Care should be taken at all times when handling Apdeck 685. Packs must be kept dry and stored above ground level. If sheets do become wet, separate and wipe sheets and place in an area for drying.

COMPATIBILITY

Lead flashings and copper alloy materials are not recommended and should not be used with or in run-off situations with ZINCALUME® sheeting. Lead head nails are also not to be used

CUTTING

Sheets are available cut to length, however, sheets may be cut using a power saw with a metal cutting blade. When cutting COLORBOND® sheeting, sheets must be laid with the coloured surface facing the ground. Ensure any hot particles or debris does not come into contact with the COLORBOND® sheeting.

CLEAN UP

To prevent premature corrosion, after each days work is completed, the sheeting area must be thoroughly cleaned of all debris, including nails, rivets, rags and especially filings from cutting or drilling.

WALKING

Clean soft soled shoes should be worn when walking on sheets.

DELIVERY

Normally delivery can be made to site within 1 to 2 days. To prevent any damage whilst unloading, we require suitable arrangements be made. If crane unloading, ensure load is spread evenly. If no crane is available, people must be on hand to assist in unloading.